With the arrival of the busy season in shipping comes a familiar set of changes: an increased volume of goods, congestion at ports around the country, the frantic rush to meet deadlines, and an aggravating shortage of chassis.

A chassis is an essential piece of equipment for shippers; truckers need to use these steel frames to transfer cargo from ships to their vehicles for land transport. Although the equipment is really nothing but a little metal and wheels, truckers can’t function without it. And although ports keep a stock of chassis that truckers can borrow for free, it’s not always easy to find the frames. Truckers then have to decide whether to spend hours trying to track one down, or rent the requisite equipment from a chassis leasing company for $17-$25 a day.

Those who choose the latter aren’t exactly off scot-free, however. These leasing companies usually have different types available, and then truckers have to go out of their way to return their rentals to specific locations. Unfortunately, it seems that in all cases the situation leads to one unfortunate outcome: congestion and frustration.

Is There Really a Shortage?

An alleged overall shortage of chassis only amplifies the organizational problems. Currently, three companies – Flexi-Van Leasing, TRAC Intermodal, and Direct ChassisLink – are responsible for most leasing transactions within the U.S. Although they own nearly 670,000 chassis between the three of them, the total number available to truckers has only increased by 2.7% in the last four years. Compare this to an 11% increase in containers coming into the United States and it’s easy to see why chassis seem so hard to come by at ports.

However, others are of the opinion that it’s not a shortage issue at all. Keith Lovetro, a chief executive at TRAC, claims that there are more than enough chassis to go around. He points to the lack of mechanics as the real problem; if workers aren’t available to maintain and repair the steel frames, then many of them sit useless in lots. Joni Casey, the president and CEO at the Intermodal Association, agrees with the assessment that the total number available isn’t to blame. Rather, she points out that, “the chassis just aren’t in the right place at the right time.”

Ports Pooling their Resources

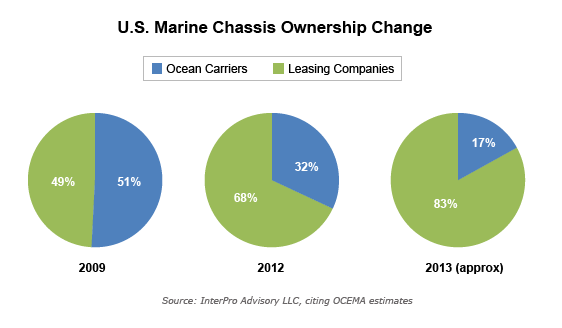

Regardless, port authorities are looking for a solution to alleviate pressure during the busy season. It’s unlikely that shippers will ever see a return to the old system, where marine shipping companies owned the chassis and lent them to truckers on an as-needed basis. Storing and maintaining the large steel frames is often more hassle than it’s worth, and shippers have been quick to opt out of the responsibility.

Photo credit: JOC.com

Instead, ports are considering teaming up to create a “gray pool” of chassis that any trucker can rent while they are at that particular location. The ports of New York and New Jersey tried implementing the idea, but conflicts over who would operate the pool and where the lot would be located caused the plan to disintegrate. The ports are currently planning for a start date sometime in October, but even that projection is vulnerable to delays.

The ports at Los Angeles and Long Beach launched a similar chassis-sharing operation earlier in the year, and some analysts are saying it shows promise (of course, these particular ports had their own sources of congestion as well).

Look South for Alternate Solutions

As with previous years, truckers may simply have to learn to accept continual problems with congestion – at least through the end of the busy season in December. In fact just recently, a terminal in New Jersey forced truckers to wait for hours before obtaining chassis materials from a local leasing organization. That being said, there are a few bright spots to which shippers can turn their gaze. For example, the new Port of Miami tunnel opened last summer that is alleviating a significant amount of traffic in Miami. Shippers may want to consider rerouting their cargo through these channels rather than risk the problems farther up the coast.

How do you plan to deal with the annual congestion problems? Do you think rerouting cargo away from busier ports is a cost effective solution? Will ports solve the chassis problem anytime soon? Let us know below!