As the one year anniversary of the PortMiami Tunnel’s opening approached, we began the task of writing an article on its first year of operation. But as we listened to Miami Access Tunnel CEO, Chris Hodgkins, during our delightful behind-the-scenes tour of the tunnel’s operations center, we realized this article would be much more than originally imagined. So we changed gears a bit, ultimately crafting the most comprehensive Port of Miami Tunnel article in the universe. An article so comprehensive, Wikipedia’s Port of Miami Tunnel page aspires to be as great as it. Enjoy!

Note: This article is also available as a white paper in PDF format. And unlike many websites these days, we’re giving you access to download with no email address required. Click here for your free copy.

Contents

- Introduction

- A Little Context

- From Start to Finish: A Five-Year Endeavor

- Helping People Day-to-Day

- Economic Impact

Introduction

As construction teams and “for hire” signs first began to flood Miami-Dade County just six years ago in 2009, it signaled the beginning of an ambitious infrastructure project that would culminate in the completion of a landmark tunnel in Miami.

The tunnel, which was designed in an effort to reduce traffic congestion around the Port of Miami, finally opened its doors (or rather raised its gates) to the public on August 3, 2014. Now that the tunnel has been fully operative for just over a year, it is the perfect time to reflect on how this colossal venture has affected city operations and improved the life of South Floridians and visitors alike.

From creating jobs and clearing traffic, to boosting the economy, the tunnel has plenty to say for itself. Thousands of people drive through the underwater passageway each day, but most give little more than a passing thought to the endeavors that allowed the tunnel to take its final form.

A great deal of planning went on behind the scene. From the start, hundreds of officials came together to strategize on ways not just to construct a tunnel, but to launch a one-of-a-kind project that would serve as a model for how such large-scale infrastructure tasks, combined with a few novel ideas and a lot of hard work, could serve the local community and pay back their tax dollars many times over.

A Little Context

What Makes Miami Different?

PortMiami is one of the most important economic centers in the United States. Not only is it the top seaport in Florida, it is the 11th largest cargo port in the nation. Miami is widely considered the “cruise capital of the world,” serving as a gateway to the Caribbean islands, Central America, and other top vacation destinations. The port is responsible for $15 billion a year in imports and exports, and $18 billion in total economic output.

Overlooking downtown Miami and PortMiami from the Miami Access Tunnel Operations Center

More than a dozen shipping companies regularly service the port, while cruise lines whisk over four million passengers a year off to exotic destinations. While this description paints a glamorous picture of a seaside city bustling with tourists and commerce, the port’s popularity has also made the region susceptible to painful congestion.

Congestion Issues

Just a few years ago, PortMiami suffered from traffic problems that rivaled downtown Manhattan. More than 16,000 cars and trucks traverse the streets surrounding the port every day, and traffic from cargo trucks makes up more than a quarter of that figure.

Prior to the tunnel project, the existing bus and vehicle routes were struggling to support the massive weight of this congestion and inhibiting further growth in the region. The city’s central business district, a portion of which lies proximal to the port, was also restricted in its development due to the extensive traffic that clogged roadways and stymied commercial growth. And traffic patterns in Miami are distinct, even from those of other big cities.

In addition to typical workday and rush hour traffic, South Florida experiences a significant uptick in congestion in the evening, especially on weekends during peak nightlife hours.

Decades in the Making

Most area residents would have quickly agreed that a change was in order, but what most did not realize was that Miami-Dade County had been discussing viable solutions since the 1980s. Thirty years ago the venture was dubbed the “Port of Miami Transportation Improvement Plan,” but lacked clear vision of how the actual plan would become reality.

It was not until the year 2000 that the Federal Highway Administration approved the project, and it would be another decade before construction crews finally broke ground on the site.

From Start to Finish: A Five-Year Endeavor

Planning Stages

What started as a grass field would soon become home to one of the greatest engineering feats in South Florida, responsible for removing nearly 1.5 million trucks from the streets of downtown Miami.

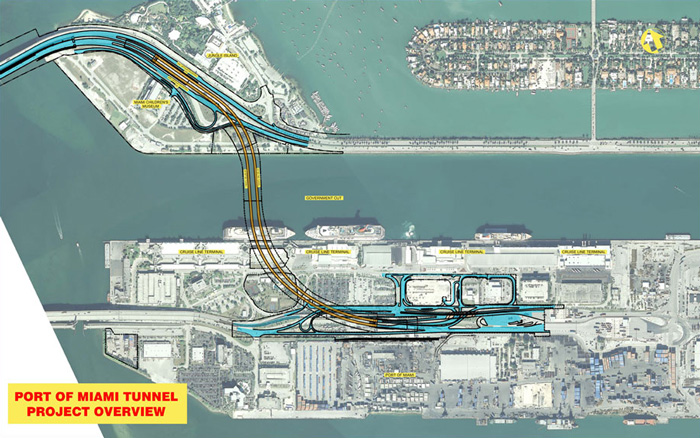

The blueprint for the tunnel was ambitious, to say the least. The plan was to construct a new road that would dip under Biscayne Bay, a waterway between Watson and Dodge Island, effortlessly whisking drivers from the MacArthur Causeway to PortMiami.

PortMiami Tunnel project overview (credit: portofmiamitunnel.com)

Today, the tunnel seems like a natural continuation of the surrounding highway, but six years before its opening, it was not so obvious how a construction crew would initiate such a project on some of the busiest roads in South Florida. As Miami Access Tunnel CEO Chris Hodgkins described the process, “It was like working in a glass bubble.”

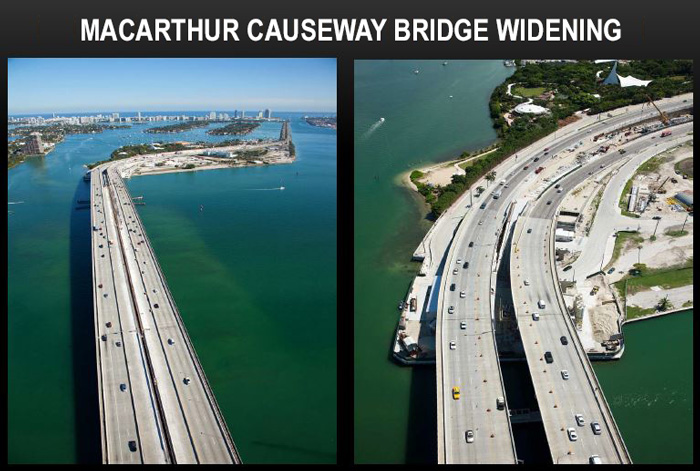

Unable to shut down the roadways during construction, project authorities had to instead revert the traffic coming across the MacArthur Causeway Bridge 100 feet to the south. They ended up expanding the roadways from three to four lanes in each direction so as not to disrupt traffic, as well as installing new pylons and girders on the bridge. This sounds like a construction project in and of itself, and yet it was all just prep work. The construction team temporarily reconfigured the roads on Dodge Island so that drivers could make a seamless transition to the port, even during construction. Workers then prepared new roads that crewmembers could install in less than twenty-four hours; continuing the effort to minimize the operation’s impact on port traffic.

(credit: portofmiamitunnel.com)

The need to tackle multiple infrastructure projects just to support development of the tunnel speaks to what a gargantuan feat this venture has been. The city may not have approved the construction had it made even the slightest (albeit temporary) negative impact on the tourism and commerce industries – industries where “time is money.”

Public Private Partnership

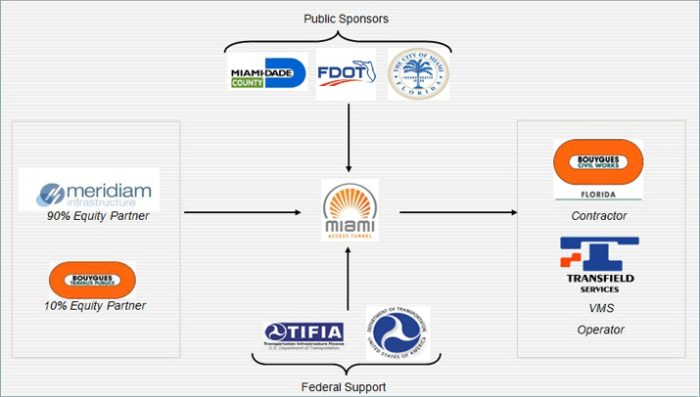

The tunnel project also exemplifies the benefits of public-private partnerships in infrastructure projects. The State of Florida, Miami Dade County, and the City of Miami all collaborated with two major private construction companies – Bouygues Civil Works Florida (BCWF) and Transfield Services – a decision that saved the government both time and money. BCWF is a division of Bouygues Construction, subsidiary of the Bouygues group, an international operation of French origin supporting more than 125,000 employees in over one hundred countries.

(credit: portofmiamitunnel.com)

Transfield Services is responsible for ongoing maintenance and operation, and although officially based in Australia, Transfield commits a great deal of its business to the United States. In addition, MAT Concessionaire, LLC, stood as an overarching authority on the project and was responsible for the official design, construction, and implementation of the tunnel, as well as overseeing the collaboration between other public and private entities.

The Transfield Services (TSI) Team outside the tunnel entrance (credit: portofmiamitunnel.com)

The network of public and private entities that came together with local and international interests to make this project a success, all while completing it on time and under budget, was quite admirable. In fact, in July of 2015 the National Council for Public-Private Partnerships bestowed on the tunnel the 2015 Infrastructure Project Award, a clear indication of how this model has spelled success for the Miami-Dade community.

The Tunnel Boring Machine, or “Harriet”

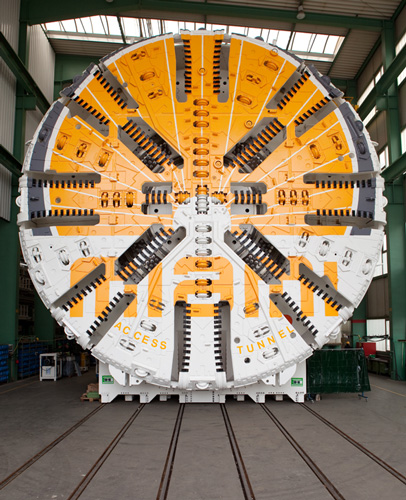

One of the most fascinating pieces of equipment used for the tunnel project was a tunnel-boring machine (TBM). This machine, which the crew constructed particularly for this project, was as long as a football field and taller and wider than a four-story building.

The Tunnel Boring Machine, Harriet (credit: portofmiamitunnel.com)

The efficiency of such a piece of equipment is astounding. It is still considered new technology, and the PortMiami Tunnel is now the largest of its kind to have been constructed using the boring technique. Such a machine, which is also known as a “mole,” can pulverize cross sections of hard rock and sand, clearing long cylindrical sections of tunnel while leaving behind a smooth wall after excavation.

An alternative to tunnel blasting, TBMs can be expensive upfront but often save a significant amount of money on projects of this size. In the spirit of community involvement, a local Girl Scout Troop named this TBM. They appropriately chose “Harriet,” a name inspired by Harriet Tubman and her tenacious role serving the historic “Underground Railroad.”

During project construction, Harriet had few opportunities to rest. The TBM worked twenty-four hours a day: twenty hours per day were spent alternating between excavating dirt and installing rings in the newly hollowed out space, with the remaining four hours per day spent on machine maintenance. It took twelve to sixteen people on board the TBM at all times to maneuver it, while an attached control room acted as base for operations.

Another room, also attached to the machine, served as a host for inspectors and other contractors who needed to keep tabs on the tunnel’s progress. An additional twelve to fourteen people worked on the surface of the machine, completing various tasks to assist Harriet as she pummeled tirelessly through thick slabs of rock.

The Tunnel Boring Machine trailing gear (credit: portofmiamitunnel.com)

A Slow Start

It took a solid eight months to complete the first tunnel because workers ran into delays caused by what CEO Chris Hodgkins dubbed “unforeseen geotechnical concerns.” In other words, the team discovered that a large amount of coral stone, a hard, porous material similar to granite, was directly in the path of the would-be tunnel.

To make matters more difficult, some of the pockets of stone, filled with a semiliquid material known as “slurry,” were as large as a city block.

To overcome this obstacle, workers had to pump more than 200,000 cubic yards of concrete underneath Biscayne Bay, filling the holes so that the TBM could cut straight through a hard surface and avoid an explosion of suspended coal, rock, and other small particles. Fortunately, project leaders were not only able to surmount this issue, but could proudly announce that they also came in under budget for this stage of the venture.

Creating Positive Impacts

During any tunnel excavation, construction teams have to deal with the inevitable issue of waste. After all, an intimidating piece of equipment like the TBM produces a massive amount of dirt and ground up concrete in a short period of time, and workers have to haul the mountains of rubble somewhere.

Ever motivated to make a positive impact on the community, tunnel authorities issued a fleet of more than two-hundred trucks to haul the rock debris down to Virginia Key each night. At the key, more crewmembers were standing by, ready to cover an existing landfill with the rock and dirt.

Ultimately, they capped the landfill and planted the seeds for a grassy recreation area. City officials are already planning to turn the mound into a community park, complete with sports fields, bike trails, and open green space.

Digging Deep and Carrying On

Next, the team had to construct five cross passages to connect the two tunnels. These passages act as emergency exits and helped workers move between the two channels during excavation, but they were also surprisingly difficult to build. While some were fairly simple to dig out, most required a crew to freeze the water in the area prior to excavating the space. Otherwise, the crew would have cut through the walls of the tunnel, straight into water, causing a blowout that would immediately flood the newly cleared passageways. To avoid a costly explosion, workers had to freeze the space to -22 degrees Fahrenheit, keeping the area cold for forty days to give the salty water time to harden.

Cross section excavation (credit: portofmiamitunnel.com)

Once the ground was completely frozen, the crew used “chippers” to slowly cut their way across to the other tunnel. This allowed just enough time to construct the passageways and install a permaseal before the water liquefied again.

Of course, there were plenty of other aspects involved in the project besides boring out a hole below ground. One of the project’s final steps involved laying down the base of the tunnel, which acted as the foundation of the roads that drivers now cruise across freely. The first twelve feet of the base consists of a dried, compacted concrete mix, topped off with a four-inch layer of porous asphalt (which acts as a pervious drainage system), and a sixteen inch thick layer of concrete. Workers had to move full-steam ahead to complete the project on time, and crewmembers were still pouring the final layers of concrete just a week before the grand opening.

Crew workers laying the final section of concrete (credit: portofmiamitunnel.com)

In fact, the very last steps of the project came together just moments before the official unveiling. Even while workers were waiting for the last layers of concrete to cure, they wasted no time zipping through the tunnel on buggies to apply the finishing touches to the project’s design. They even laid tarpaper and plywood down on the concrete as it was drying so they could continue working, keeping the project on pace. As far as the team was concerned, this was simply what it took to ensure the job was completed both correctly and on time. As they say (and as was a common expression for the duration of the project) “time is money!”

(credit: WSVN.com)

The Tunnel’s Final Form (an Unexpected Icon)

Ultimately, it took five years to complete the project. The tunnel ducks 120 feet below sea level as it traverses across Biscayne Bay, opening up on Dodge Island, offering a smooth transition right to the port for cargo haulers and cruisers alike.

An imposing portal greets drivers as they approach the tunnel entrance. Although not originally intended as a particularly stunning architectural design, the portal has quickly become an iconic view and a welcome greeting for Miami travelers. Tunnel authorities saw the massive, empty slabs of concrete as a blank canvas, which lead to engravers adorning the space with various forms of the Latin word for travel – “Navigare.” At one point, Hodgkins joked, “after four years of Latin in college, this was the first time [he had] ever used it.”

PortMiami Tunnel entrance (credit: portofmiamitunnel.com)

The completed specs of the rest of the tunnel are equally impressive, with 11,888 individual segments making up the twin tunnels, bringing together an underground channel that spans more than 4,000 feet in each direction. The diameter of the inside of the tunnel reaches nearly forty feet, leaving room for multiple lanes and a comfortable experience for drivers.

The finished tunnel is revolutionary, complete with the latest technological safety features to accommodate drivers, including dozens of security cameras, jet fans to circulate air, and a messaging system that alerts drivers to tunnel regulations and warns them of any accidents ahead.

Driving through the completed Miami Tunnel

Helping People Day-to-Day

A Smooth and Seamless Experience, Eventually

The first day the tunnel officially opened was a booming success, albeit with some typically expected hiccups. As if to test the operators’ true preparation for mishaps, one of the very first trucks to pass through actually broke down inside the tunnel within minutes of the completed project’s opening. Fortunately for the crew, they were prepared from day one and were able to immediately send in a Miami Tunnel pickup truck to assist the vehicle.

Miami Tunnel tow truck (credit: portofmiamitunnel.com)

This type of response was not limited to the Grand Opening – employees are continually working inside and out of the tunnel to ensure drivers have the best possible experience. Officials even keep a flatbed truck on site specifically to service sports cars and other exotic vehicles that are so characteristic of South Florida. Of course, these types of issues do not arise on a daily basis, but the tunnel operators pride themselves on being ready for nearly anything at any time.

Drivers whisk through the tunnel with ease, using the phrase “Cruisers Left, Cargo Right” to remember a set of simple navigation instructions. Families on their way to an island vacation in the Caribbean (and anyone else not planning to pick up a shipment at the docks) sticks to the left lane, while lumbering trucks and other hauling vehicles huddle to the right, offering a confusion-free trip even for first time Miami visitors.

Notably, there is no toll for entrance into the portal, a benefit that separates the Miami Tunnel from other cost-intensive infrastructure projects around the country. In exchange for a free pass, operators simply ask drivers to respect a few simple rules: the speed limit is thirty-five miles per hour at all times, pedestrians and bicyclists are absolutely prohibited from entry, and no hazardous materials are allowed. Drivers are also asked to respect all lane control signs and to be especially careful around cargo trucks due to their large blind spots.

The First Three Priorities are Safety, Safety, Safety

Understandably, authorities of the Port Miami Tunnel have made it abundantly clear that safety is a top priority. Operators have outfitted the area with every high-tech security mechanism that one could expect, including a state-of-the-art “Automatic Incident Detection” system. This incredible automated system constantly scans the tunnel for “deviants,” defined as any anomaly in the typical pattern of behavior along the roadway. An accident, a stopped vehicle, flames or fumes, or a pedestrian walking along the side of the tunnel could all trigger an alert in the system, indicating to the workers on duty that something is amiss.

In order to truly keep the tunnel water-tight at all times, the crew had to forgo the installation of vents that would have helped air circulate freely through the tunnel, but would have also made the passageway vulnerable to water leaks. Instead, the design called for the installation of jet fans, which drivers can see prominently hanging from the ceiling as they make their journey under Biscayne Bay.

Jet fans in Miami Tunnel during construction (credit: portofmiamitunnel.com)

The tunnel boasts a myriad other safety features as well, making it one of the most secure tunnels in North America. In fact, the submerged underpass represents an accumulation of the most-high tech safety mechanisms available for infrastructure projects in the United States – a fact immediately apparent with just a quick glance at the finished design plan.

Engineers researched many of the past disasters that have affected tunnel operations around the world, and took a preventative stance for this project.

For example, a few years ago a truck caught fire in the Mont Blanc Tunnel in France. The flames quickly spread to surrounding vehicles, resulting in multiple fatalities, and ultimately the channel was forced to shut down for two years. Learning from tragedies like this, the team in Miami fireproofed the tunnel’s internal surfaces and installed a deluge system that can quickly suffocate flames with a steady downpour of water.

There are ninety-one CCTV security cameras stationed at various points within the tunnel, all of which connect to a central command center above ground. Trained and experienced operations personnel, who are on duty twenty-four hours a day, seven days a week, 365 days a year, constantly monitor the cameras looking for even the slightest sign of trouble.

Security camera monitoring room at the PortMiami Tunnel operations center

The tunnel is also equipped with infrared sensors that scan vehicles as they approach the entrance portal. One of the sensors’ primary purposes is to alert personnel to trucks that are over the maximum allowable height. If a tall truck passes through the scanners, an alert is immediately sent to the control center, triggering a series of additional alerts that the driver will see (and hear) as he or she continues unsafely toward the tunnel. First, a ship’s horn blasts an additional warning to the driver, after which an emergency message board flashes “OVER HEIGHT” and urges the truck not to enter the tunnel. A row of red flashing lights will then serve as an additional warning, after which a net of low-hanging chains scrapes the top of the truck – an obvious indication that the vehicle’s height exceeds safety recommendations. If that is not enough, two gate arms and one final flashing sign warn the driver not to enter the tunnel. Shockingly, some truckers have made it to this point before stopping. If they have decided to continue forward, the gate arms would be enough to finally stop them in their tracks.

CCTV footage of oversized truck being stopped before entering the tunnel (credit: portofmiamitunnel.com)

The Ingenious Floodgates

The enormous floodgates are a particularly noteworthy feature on the tunnel’s long list of safety enhancements. Each of these metal gates – hidden within the engraved slabs of concrete above the tunnel’s entrance – weigh in at a whopping fifty-five tons each.

In the event of a flood, crewmembers lower the massive gates, which are equipped with a rubber permaseal, to block the tunnel’s entrance and prevent water from rushing into the empty cavity. While this might seem like an abundant precaution to some, the engineering feat was inspired by many of the nation’s other natural disasters gone awry – including Hurricane Sandy, which quickly flooded the Lincoln Tunnel and caused a devastating amount of damage.

By completely sealing the tunnel off from storm surge, port operators can minimize the destruction of even the most formidable storms. In the event of serious warnings, such as a Category 3 hurricane, it will take authorities just seventeen minutes from the time they receive notice from the Coast Guard to vacate the area and lower the gates into place. In between these stormy sessions, the gates remain safely elevated in the tall recesses of the tunnel’s exterior, hidden within the gigantic concrete slabs that signal drivers’ approach to PortMiami.

Ongoing Maintenance Benefits Drivers

In addition to all the preemptive safety mechanisms that work to keep Miami drivers secure, tunnel operators also perform frequent maintenance in order to address issues before they become problems. Maintenance crews discretely enter the tunnel from 9:00 P.M. to 5:00 A.M. twice a month, when tunnel traffic is at a minimum, to do everything from washing the walls to checking the light bulbs. Keeping the tunnel presentable and clean is a priority for the maintenance team who knows that a “shiny” tunnel will help keep visitors happy, and people may be surprised at how easily this underwater channel accumulates dirt.

The crew performing regular preventative maintenance

(credit: portofmiamitunnel.com)

For example, when a double decker tour bus passes through, there is the occasional upper deck passenger that will actually stand up and attempt to run their hands along the tunnel’s upper walls. Of course, the bigger concern here is safety – tourists who stick their hands up towards one of the tunnel’s forty-four jet fans are asking for trouble, and operators are standing by behind the control center monitors to make sure these visitors do not compromise their safety.

Double decker bus as seen from tunnel CCTV footage

(credit: portofmiamitunnel.com)

At the end of the day, everything about the Miami Tunnel comes down to safety and staying on schedule. Whether they are checking the valve pumps or updating the Automated Incident Detection System, the team functions like a well-oiled machine.

After a year of constant operation, authorities are proud to look back over a clean track record, although they cannot quite claim an “incident free” tunnel on its first anniversary. But no matter what bizarre events have occurred inside – including the time a man stole a police car, sped straight through the tunnel, and collided with the Miami Dade Search and Rescue Rapid Response Team – operations personnel have responded in kind; shutting down the passageway when necessary, and mitigating the consequences of everything from fender benders to the pursuit of criminals. That being said, not all incidents are of a tragic nature. Tunnel operators showed their hospitable side when accommodating recording artist Pit Bull’s request to shoot part of his music video in the tunnel and around the port.

Bringing the Tunnel to the People

Amidst all this talk of construction and safety, it is important to remember that this project emerged for one primary reason – to make Miami citizens and business owners happy. So far, the response from those affected has been overwhelmingly positive. Shippers and cargo haulers see more efficient operations, and cruise lines are able to welcome happy vacationers who arrive to the ship on time.

The operations team maintains that it is all about communication and accessibility, and it is constantly putting out more information to help residents make the most of their tunnel experience. The tunnel has its own website, portofmiamitunnel.com, which offers up-to-date reports on area traffic, lane closures, tunnel maintenance, and more. Drivers can even click to the website to see suggestions for alternate routes and can tune into an FM radio station to hear instructions in the case of an incident inside the tunnel. The website also offers specific directions for a variety of incident types, including what to do if a passenger experiences an injury or if a vehicle catches on fire.

Economic Impact

Operation 305

One of the most interesting aspects of the PortMiami Tunnel project has been what construction authorities dubbed Operation 305.

In response to the outrage over the construction terms of Marlins Park, Buoygues Works and other contractors committed to a major recruitment undertaking right in Miami Dade County. Project managers extended this commitment not just to workers, but to vendors involved in the process as well.

The project officially created more than 6,000 new jobs, and approximately 83 percent of those positions went to deserving community members in Miami Dade County.

Furthermore, of the 800+ businesses that had a hand in the project’s development, more than half are owned and operated within the county. When all was said and done, the tunnel project poured a full $400 million into the hands of local residents and business owners.

Miami Access Tunnel CEO, Chris Hodgkins, discussing Operation 305

(credit: portofmiamitunnel.com)

Right from the start, Operation 305 was a transparent one, keeping details of hiring and construction procedures open to the public. This was particularly important to win the public’s favor after the Marlins Park deal, which many saw as “owner friendly,” leaving locals feeling jilted. Operation 305 was able to win over the region’s most skeptical onlookers. Not only because hiring was done locally, but also because contractors placed special attention on making sure women and minorities received a fair share of the newly created construction jobs.

Short- and Long-Term Benefits to Commerce

The economic benefits of the Miami Tunnel span far beyond new jobs – both temporary and permanent – that the project has supported. The tunnel continues to generate billions of dollars in economic impact and contribute to annual income within the city as the transportation industry booms. Although some initially criticized the tunnel and its cost to taxpayers, the entire project actually came in a whopping $90 million under budget – a financial feat practically unheard of for infrastructure ventures of this size. Even President Obama made a stop at the construction site to share his positive views on the project.

Obama speaking at PortMiami in 2013 (credit: whitehouse.gov)

“Breaking ground on more projects like this tunnel that I just saw means more good construction jobs that can’t be outsourced. They have to be done right here in America, and they end up giving people good pay and good opportunities to raise their families.”

–President Barack Obama

Quality of Life Matters

The tunnel has also been a substantial success in its ability to improve the quality of life for Miami residents. Even those landing at the airport now enjoy a smoother ride, as they can avoid Biscayne Boulevard altogether and connect directly to the tunnel on their way to the port.

An average of 14,000 vehicles traverse the underpass each day, and even with nearly 400 minor and major “incidents” to date, there has not been a single fatality. As far as traffic is concerned, a project like this one could not have come soon enough. Estimates suggest that the amount of truck traffic in Miami will double by 2030, a figure partially influenced by the increased business the port will handle following the completion of the Panama Canal expansion project.

Preparing for Post Panamax Business

As Miami Access Tunnel CEO Chis Hodgkins put it, shipping in and out of Miami after the completion of the Panama Canal expansion project will simply be “bigger, better, quicker, and more of everything.” The canal expansion is expected to have a positive effect on both cargo and cruise operations in South Florida, so the tunnel came just in time to mitigate what may have otherwise been a logistical nightmare.

Scheduled to open in April of 2016, the canal expansion (the first major construction endeavor since its opening in the early 1900s) will broaden the canal’s waterway and make the port more accessible to supertankers and other large vessels. This will allow these larger freight haulers to travel from faraway countries in Asia directly to East Coast ports, including PortMiami.

Ports all along the East Coast, from New York to Georgia, are making adjustments in order to accommodate the increased volume of ships. Opening the PortMiami Tunnel is just one way South Florida is aiming to stay ahead of the game and maintain its position as one of the most important cruise and cargo destinations in the world.

Concluding Thoughts

Upon final reflection, it is easy to see how projects like the Miami Tunnel are working to benefit residents on a daily basis and improve the community. At a time when there is waning support for costly government initiatives, and many are quick to criticize the upfront expense of massive infrastructure works, the Miami Tunnel exists as an important example of smart investing.

On a communal level, that is what an investment is: people making some form of short-term sacrifice in order to achieve their vision of a better future. What is most striking about the tunnel project is that through ventures like Operation 305, Miami-Dade County was essentially able to begin reaping the benefits from day one. Today, the Miami Tunnel – like all smart investments – continues to turn short-term dollars into long-term economic output with a better living for South Floridians.

The Port of Miami Tunnel is truly the tunnel that keeps on giving.

2 Comments on “PortMiami Tunnel: The New Standard in Transportation Infrastructure”

This Tunnel has been one of the best things for the Port of Miami.

It just changes the traffic pattern inside and outside the Miami Port.

Before this Tunnel the traffic was a mess, specially on Fridays and Mondays and during any special event at the Downtown Miami.

After this construction finished we can commute from/to Port of Miami easy and without the pain we had in the past.

Port of Miami is the busiest cruise terminal in the world and handle millions of passengers every year, meaning a lot of traffic going in and out of the terminals.

Definitely this tunnel has been an amazing idea.

Hi Myleydys – we completely agree!